Storbåtsegga (project title “Hydra”) is a semi-closed production tank with a capacity of 3,120 tonnes of salmon. The unit has a sealed roof and walls extending down to 20 meters below the sea surface. The enclosed structure is designed to prevent lice and disease-causing microorganisms, which generally move in the upper layers of the ocean, from entering the tank. The Ocean Tank is also engineered to prevent fish escapes, as all materials in the construction are significantly stronger than those used in today’s open-net fish farming pens.

Through a manually controlled water exchange system, adapted to the strong ocean currents at the site, continuous access to fresh, oxygen-rich seawater is ensured. At the same time, the open-bottom design allows fish waste to be naturally dispersed by the current.

The result is a robust and innovative solution that promotes good fish welfare, with reduced risk of lice, disease, and escapes. This is an important step toward a more sustainable and forward-looking aquaculture industry.

KEY FIGURES:

| Height | Approx. 50 meters from bottom to top |

| External diameter | 78 meters |

| Internal diameter | 60 meters |

| Production volume | 86 700 cubic meters |

| Maximum allowed biomass | 3120 tonnes |

| Operational draft (hull) | 30,6 meters |

| Operational draft (including net) | 49,4 meters |

| Maintenance draft | 11,5 meters |

| Feed storage | 200 tonnes |

| Energy sources | Shore power, backup diesel generator, emergency generator |

| Weight | 6000 tonnes (15.000 tonnes with ballast water) |

News and updates

Updates:

- November 23rd 2025: Storbåtsegga was towed by the transport vessel GPO Emerald in beautiful winter weather — a large, synchronized operation planned down to the smallest detail.

- November 22nd 2025: Arrival at the site “Sørvika” on Saturday morning/late morning.

- November 21st 2025: Storbåtsegga arrived in Vesterålen and could be seen from Melbu/Fiskebøl in the early afternoon.

- October 30th 2025: GPO EMERALD departs northward carrying Storbåtsegga

October 23rd 2025: Storbåtsegga is loaded onto the vessel in Turkey

January 31st 2022: Agreement signed with Turkish shipyard group Gemak for construction of the production tank

February 2021: Nordlaks acquired the “Hydra” project

April 2018: The Norwegian Directorate of Fisheries grants four development licenses to Hydra Salmon Company AS (“Hydra”) for the development of semi-closed aquaculture technology

Images and videoes are available for downloading here. Please credit the photographer/Nordlaks. The album is updated regularly.

Why Nordlaks has chosen this technology

A semi-closed production tank provides a physical barrier against the upper layers of the sea where salmon lice are most prevalent. What makes this concept unique is its system for water exchange and circulation within the structure.

Nordlaks views the technology in this project as an important contribution to the continued development of the company and to the technological diversity of the aquaculture industry. By realizing this project, Nordlaks will build competence in the design and operation of semi-closed systems, with expected benefits in terms of both escape prevention and biosecurity, particularly regarding salmon lice control.

How does The Ocean Tank work?

The Ocean Tank consists of a sealed, cylindrical structure submerged in the sea, with a floating ring at the top and a closed roof. The tank is watertight down to about 20 meters, protecting the fish from salmon lice and diseases that move in the surface water. Below this, from 20 to 27 meters, the tank is open to the sea (closed only with a metal mesh).

At the bottom of the structure are fixed guide vanes, angled ribs that direct seawater naturally in and out of the tank. This ensures continuous water exchange and circulation, providing the fish with fresh, oxygen-rich seawater without drawing in surface water.

At the base, oxygen diffusers and compressor hoses are installed to aerate the water during naturally low-oxygen periods, for example during tidal slack when currents stop. Circulation pumps can also be added in strategic positions if needed to secure optimal water flow inside the tank. Organic waste sinks through the open bottom and is naturally dispersed by ocean currents.

Watch the illustration video here:

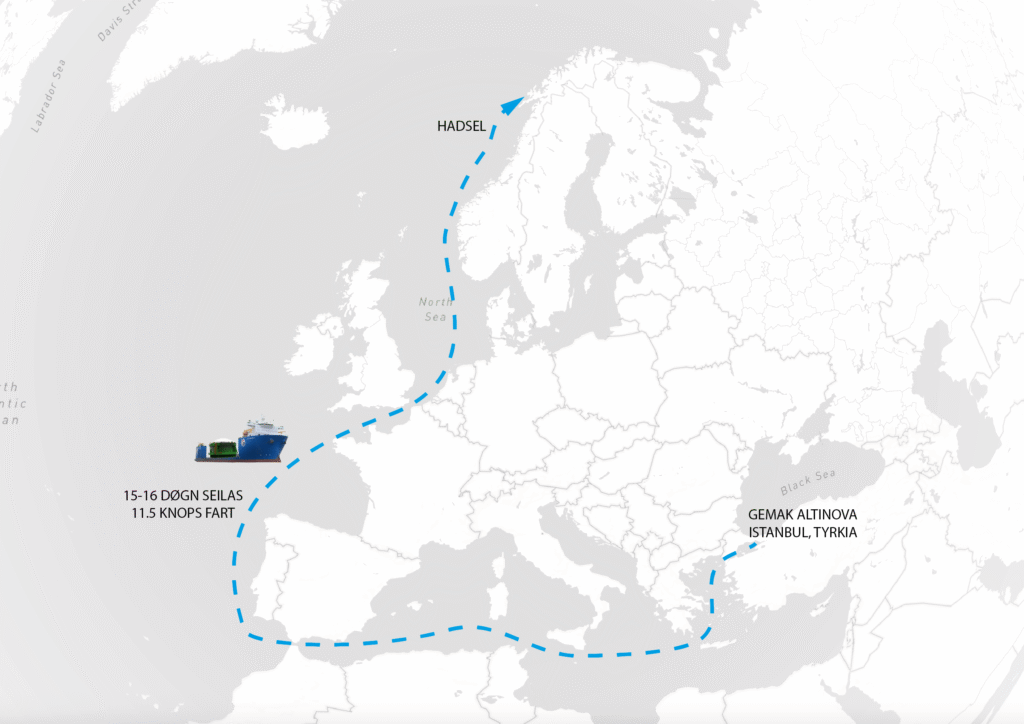

Sailing route

Storbåtsegga is transported on the deck of GPO EMERALD from the GEMAK shipyard in Turkey. The northbound voyage takes between two and three weeks.

The unit will be unloaded in Ingelsfjorden, in Hadsel Municipality.

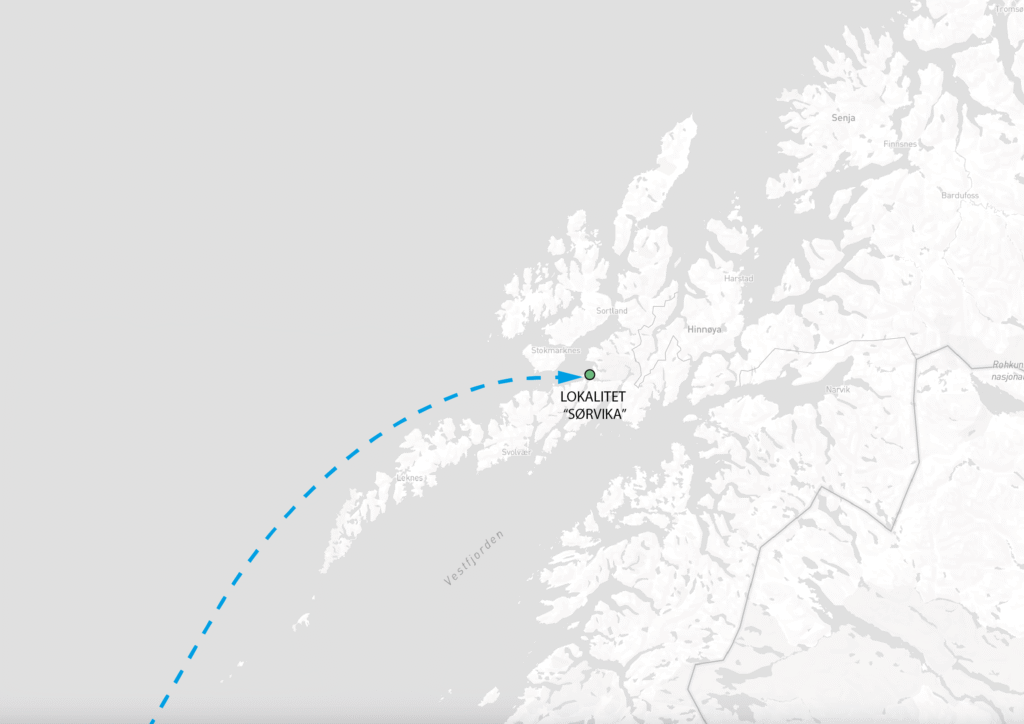

Storbåtsegga will be unloaded before being towed to the Sørvika site in Raftsundet, where it will be anchored.

About Storbåtsegga

On April 6, 2018, the Norwegian Directorate of Fisheries granted four development licenses to Hydra Salmon Company AS (“Hydra”) for the development of their semi-closed aquaculture technology called the Production Tank.

In February 2021, Nordlaks Oppdrett (“Nordlaks”) assumed responsibility for Hydra, and began completing the design and realization of the project in accordance with the Directorate’s permit.

When Nordlaks acquired the Hydra companies, we got all rights to the technology, project foundation, and related development licenses. During the transition, there was continuous dialogue with the Directorate of Fisheries.

After the acquisition, Nordlaks collaborated with NSK Ship Design in Harstad, which led the process toward final design verification and preparation for tendering to shipyards. The Turkish shipyard GEMAK was chosen to construct the tank and install systems from subcontractors. All subcontractor agreements are handled by the shipyard according to Nordlaks’ specifications. Nordlaks has followed the construction process closely with on-site supervision throughout.

All essential systems required for aquaculture operations are integrated into Storbåtsegga. The structure is self-sufficient, requiring external support only for major operations such as fish transfer or feed delivery. The unit is designed as an “unmanned facility,” meaning operators will not live on board but will visit daily. A high degree of automation and remote monitoring will be implemented. Remote control will be used where practical, for example for fish feeding. Storbåtsegga has an integrated feed storage system and is therefore independent of a separate feed barge. It will be connected to shore power, with both backup and emergency generators in case of power outages.

The unit consists of three main parts: surface module, tank/hull wall, guide vane module.

Surface module:

The surface module consists of a circular hull and a dome-shaped roof section. The hull (surface module, tank wall, and guide vane module) is made of steel. The roof trusses are also steel, while the outer roof covering is made of a lighter material. The module is sealed except for air intake and exhaust.

The hull has an inner diameter of 60 meters and an outer diameter of 72 meters at the surface. The surface module contains feed storage, engine room, workshop, and a dead fish handling system, among other installations.

Tank/hull wall:

The sealed hull wall extends from the surface module down to about 20 meters below the waterline. It functions as a physical barrier, protecting the fish from environmental impacts. This section also includes columns and a lower pontoon, with ballast tanks and buoyant volumes providing stability, buoyancy, and strength during construction, transport, installation, and operation.

Guide vane module:

This is a rigid, permanent part of the structure made up of vertically and horizontally angled steel plates (“guide vanes”) that run along the lower circumference of the tank wall. The function of this section is to harness the natural current to create water circulation and exchange inside Storbåtsegga without the need for active energy input. An auxiliary water exchange system will also be installed to ensure water quality and fish welfare under all current conditions.

The Ocean Tank has a capacity of up to 3,120 tonnes of salmon (four development licenses). It is designed to operate without permanent staffing, similar to conventional aquaculture facilities. The unit does not depend on a feed barge and will be powered by electricity from shore. Several operations can be remotely controlled, including feed intake hatch operation, camera monitoring of fish and equipment, and fish feeding. The tank is cleaned using a remotely operated underwater vehicle (ROV) during production and between production cycles. It is equipped with two quays for docking and mooring of personnel transport, service vessels, and other support craft. Storbåtsegga will be located at the high-current site Sørvika (location no. 13936) in Hadsel Municipality.

| Leverandør | Beskrivelse |

|---|---|

| Akva Group | Bulk Handling Plant for Fish Feed Pellets |

| Akvaplan NIVA | Environmental measurements and monitoring |

| Alfa Laval | Heat Exchangers |

| Allweiler | Pumps |

| Anadolu Flygt Pompa | Ensilage Room Bilge Pumps (Wet Pit Pumps) |

| Autronica | Fire Detection System |

| Bachofen AG | Level Switches |

| Besi | Remote Controlled Ballast Valve System |

| Bohamet | Windows and hatches |

| Bretteville | Trolleys & Hoists |

| Brodrene Dahl | Valves |

| C.C. JENSEN | Filtration Units |

| Cathelco | ICCP; ICAF System |

| CoastDesign | Loading Computer Software |

| DNV | Classification and accredited services under the NYTEK regulations |

| Eltorque | Electric Operated Actuators |

| Emerson | Transmitters |

| Evotec | Net Handling System and Net Rigging; Deck Cranes; Deck Winch; Capstans |

| Fendertec | Fenders |

| Force Technology | Wind tunnel testing and analysis |

| Frank Mohn | Ballast Pumps |

| Gemak Gemi Insaat Sanayi ve Ticaret A.S. | Design and construction of hulls, installation of marine systems |

| Glamox As | Lighting Equipment |

| IMS | Watertight Sliding Doors |

| İKS Yapı (Cookson) | Roller Gate |

| ITEAM 1 AS | Nautical Equipment (UHF, AIS, etc.); 2-way VHF Portable Radios for Survival Craft |

| Keyparts (Kaeser / Vega) | Condensate Drain Tanks; Level transmitters; Remote Tank Sounding System |

| Kongsberg / Kongsberg Maritime AS | Water Injection System; Pressure & Temp. Transmitters for Ballast Pumps |

| Libra-Plast | External Doors |

| Maccaferri | Net Inlet Grid (Mesh Net) |

| Mariner Systems (UK) Ltd | Loading Computer Hardware |

| Marioff | Hi-Fog Fire Protection System – Watermist System |

| MTU | Diesel Generator Set |

| Multiconsult | Hydrodynamic analyses. Metocean data/site report |

| Nilfisk | HPFW Unit |

| Nogva | Emergency Diesel Gen-set |

| Nortek Group | ADCP Sensors |

| NSK Ship Design | Design and system integration |

| Optimar | Dead Fish Handling System (main contract) |

| PG Flow Solutions | Service Cooling Pump |

| Scale Aquaculture AS | Signal Lights |

| Seasystems | Anchoring & Mooring Equipment (Fairlead Chain Stoppers) |

| Selstad | Nets |

| Siemens | Keycard System |

| Siemens AS | Integrated Alarm System Aquaculture |

| Siemens Energy | Marine IAS |

| SINTEF Ocean | Model testing and analysis |

| Teknotherm | HVAC System |

| Tensaform | Engineering of Roof Structure, Roof Covering Membrane System |

| TMC | Compressed Air System |

| Viking Life-Saving Equipment | Life Rafts; Life Saving Appliances; Fire Hoses, Fire Cabinets & Jet Nozzles |

| Zenitel Norway | CCTV System; PA/GA System |

Questions?

Contact:

Heidi Ryste, head of marketing and communications: heidi.ryste@nordlaks.no

Kolbjørn Hoseth Larssen, communication advisor: kolbjorn.larssen@nordlaks.no